Our workspace is split in three rooms each operative for the different checkpoints of our restoration process.

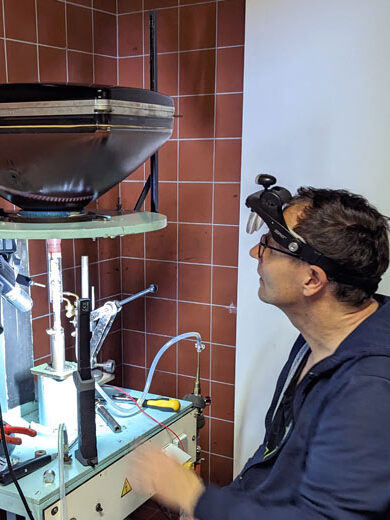

The first stage involves the overhaul of all electronic components.

For the case that the tube will not meet its desired emission, we have industry-grade machinery to give the tube a new life cycle.

The old system gun of the picture tubes gets cut out of the glas neck and a new one gets melted in.

This process requires antique industry machinery that was reworked and can only be completed by experts.

Thanks to our broad selection of guns for all kinds of CRTs, we are able to renew almost every tube today.

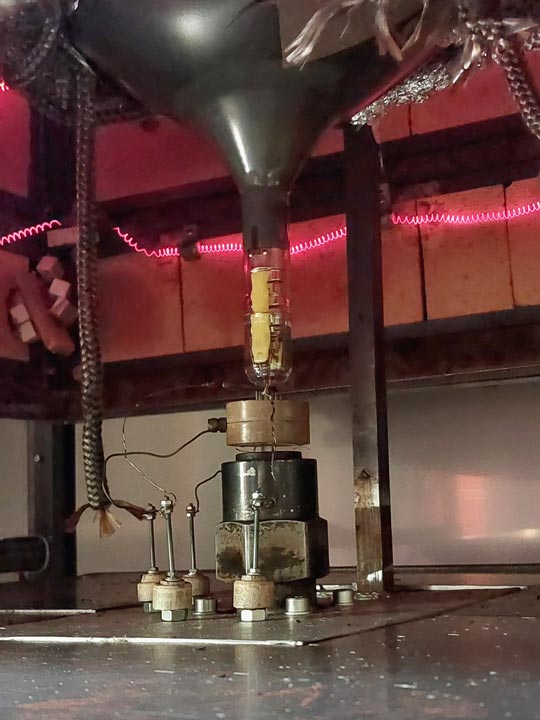

After successful installation of the new system gun, the tube needs to be set under high vacuum.

Our high vacuum oven evacuates the tube using a oil diffusion pump and a

400°C heating cabinet.

Several other steps are done at the end to „start“ the rebuilt tube.

The History of Colorvac

Founded by Peter Draheim in 1964, Colorvac was working as a renewal service for CRT screens.

In the times of the CRT TV, people would get their faulty picture tube overhauled rather than buying a new TV set.

Even back then, Colorvac was known for its speciality in being able to renew every type and brand of tube.

This was not common at all, since most renewal workshops only offered recent or certain models.

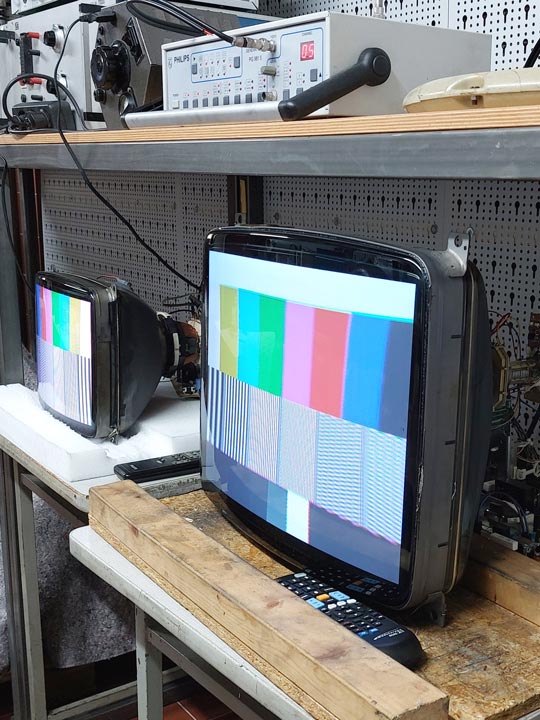

When the worldwide market put its focus on LCD technology, all rebuilding stations were forced to close.

Years after the global end of the CRT, the Kunstpalast Düsseldorf reached out to

Christian Draheim asking for a restoration of the work

Fish Flies On Sky by Nam June Paik.

All equipment was trashed many years before, but in order to save thousands of CRT-based artworks around the world, Christian Draheim decided to rebuild the former workshop from the top of his head.

Since then, Colorvac is on the mission to preserve CRT-based art for the future.